Products

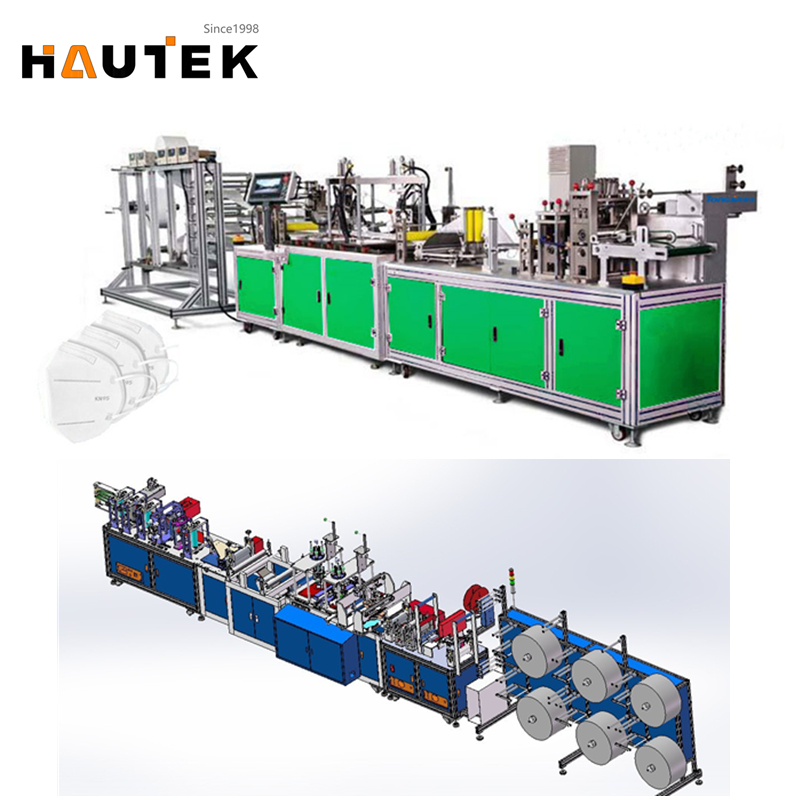

PP Meltblown Nonwoven Machine/Production Line

Five Advantages Of Products

- Effectively reducing energy consumption

- Uses automatic control systems

- Working stablly

- Advenced technology

- This production line has a leading position in China

Product Details

Equipment introduction

JG-RPB1600 PP meltblown non-woven production line process introduction:

The melt-blown nonwoven process uses high-speed hot air to draw a thin stream of polymer melt extruded from the spinneret of the die, thereby forming ultra-fine fibers and condensing on the curtain net or roller, and relying on itself It becomes a nonwoven fabric.Process standard flow:

Polymer preparation → Melt extrusion → Metering pump → Meltblown die head assembly → Melt thin flow stretching → Cooling → Receiving deviceJG-RPB1600PP meltblown non-woven fabric production line configuration:

Product requirements

Effective width of the product 1600mm;

Maximum package roll diameter 1200mm;

Output: 1.5-2.0T / 24 hours (based on 20g per square meter);

Monofilament fineness 2um-5um;

Main raw materials Polypropylene chips (special materials for meltblown)

Product weight: 15-200g / m2.

Mechanical speed: 10-80M / min;

Installed capacity: 450kw;

Equipment size: about 16000mm × 6000mm × 6000mm

JG-RPB1600PP meltblown nonwoven production line technical parameters

1) Extruder 1set

Loading work platform 1set

Vertical mixer (stainless steel)1T 1set

Vacuum automatic feeding system 1set

Hopper type Tapered stock storage type

Hopper volume ≥200LB、Driving motor Three-phase AC motor (Siemens Motor)

Drive power 55KW

Speed regulation method frequency converterC、Reducer 1set

Type Gear box for plastic machinery

Gear material 20GrMoTi high-quality alloy steelD、Barrel

Diameter Φ105mm

Material 38CrMoAl high-quality alloy steel is surface hardened by ion nitriding

Nitriding depth 0.5-0.8mm

Surface hardness HV 850-110

Heating method electric heater

Temperature control mode PID intelligent temperature control instrument automatic controlE、Screw

Diameter Φ105mm

L / D ratio 30: 1

Material 38CrMoAl high-quality alloy steel is surface hardened by ion nitriding

Nitriding depth 0.5-0.8mm

Surface hardness HV 850-11002) Hydraulic screen changing system 1set

Screen changing method Double station plunger type hydraulic quick screen changing

Oil pump driving form AC motor

Oil pump driving power 2.2KW

Heating method stainless steel electric heating

Pressure sensor 1set3) Melt metering pump 1set

Drive motor 3 KW

Control form frequency control

Pressure closed loop system 1set

4) Hanger-type melt-blown extrusion molds 1set (domestic brands)

The template material is made of alloy steel, after quenching and tempering, heating method using heating tube in the mold internal rod heating.

Product width 1600mm

Total heating power 35 KW

Pressure sensor in front of the mold 1est5) meltblown spinnerets 2sets (First send 1 set when delive, another set will send when produce finish)

Made of precision high temperature resistant steel, each set includes: aluminum gasket, distribution plate, multilayer stainless steel mesh6) Air heating system

Heating tank material stainless steel

Heating medium air

heating power about 180KW

Maximum design heating temperature 400ºC

Operating temperature 200-350 ºC (adjustable)

Temperature control method Intelligent temperature control PID automatic control7) High pressure fan one set

Control power 110KW

Control type AC variable frequency control

Supply air pipe one set8)Networking system one set

Suction port adjustment Adjustable air outlet

Net curtain 2pieces

Conveyor width 1900mm

Mesh material PE mesh

Negative pressure fan 1sets9) Electrostatic electrets one set

Input voltage 220V

Output voltage 60 kV

Processing width 1.8m10) Winding one set

Friction roller 1 root(steel roller)

Roll length 2000 mm

Surface treatment of steel rolls:Rubber-coated polishing

Control power 5.5KW

Control type Frequency Control

11) Electrical control system

PLC control, inverter synchronous control,

Main motor Siemens Motor

Main low voltage electrical appliances: Schneider brand

Temperature control instrument: Omron or RKC13、 Accessory equipment

Calciner one set

Ultrasonic cleaner one set

Air compressor one set

Note: The above contents are for reference only.Hautek reserves the right to change without notice.

Ningbo Hautek Import & Export Co.Ltd.

Contact Person: Frank Huang

Telephone: +86-13805862932

Landline: 0574-87317986

Company Address: 831,No.598 Jiangnan Rd., Ningbo, China P.C.315040.

Website: hautek.us764.com

Previous: KN95 Face Mask Making Machine/Pro...

Next: No