Products

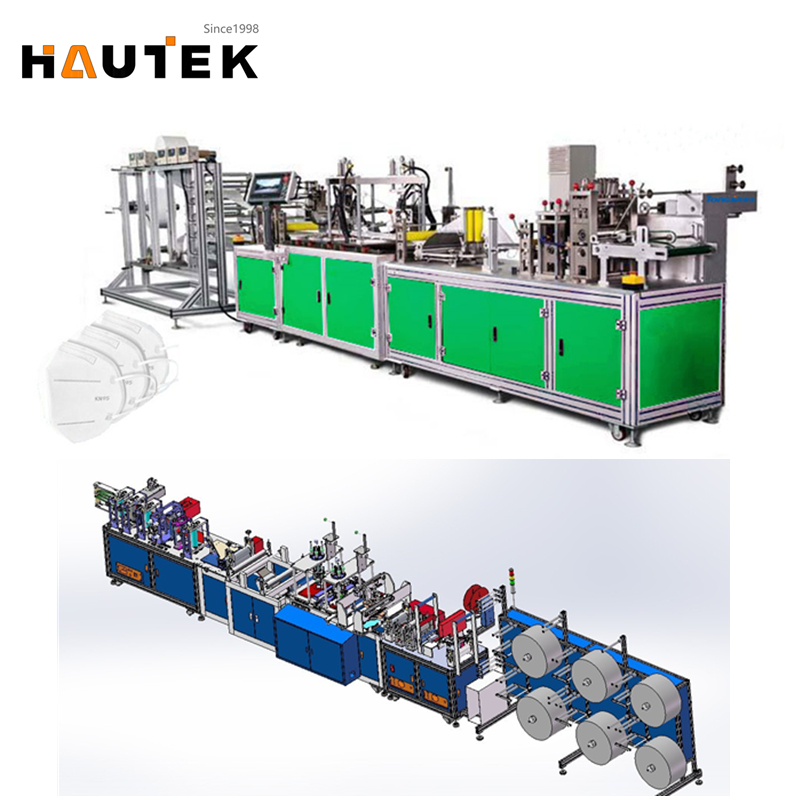

KN95 Face Mask Making Machine/Production Line

Five Advantages Of Products

- KN95 mask is composed of 6 layers of special filtering non-wowen, which meets the NIOSH standard filtration rate of 95%.

- It can effectively filter certain microbial particles (entering viruses, bacteria, etc.), avoid cross-infection of droplets and protect human health.

- Uses optimized design technology, and uses automatic control systems across the entire line

- Effectively reducing energy consumption to a minimum.

- Increased efficiency to a higher level.

Product Details

Features of KN95 mask production line

KN95 mask is composed of 6 layers of special filtering non-wowen, which meets the NIOSH standard filtration rate of 95%. It can effectively filter certain microbial particles (entering viruses, bacteria, etc.), avoid cross-infection of droplets and protect human health.

The KN95 mask production line adheres to the corporate philosophy of "technology creates excellence", integrates the essence of decades of machine manufacturing experience, uses optimized design technology, and uses automatic control systems across the entire line, servo tracking welding, effectively reducing energy consumption to a minimum. Increased efficiency to a higher level. This production line has a leading position in China and is currently the most

promising investment project.

1. Production process description:

The production line has 6 cloth trays and a nasal bridge unwinding tray, which can produce up to 6 layers of N95 masks. Each unwinding has a lack of material alarm and tension adjustment. The rolls are stacked in, and at the same time they are placed in the bridge of the nose. Weld multiple layers of fabric together by ultrasonic welding, and press out various patterns, and then punch out the valve hole of the cover. Carry out trademark printing and automatically weld the earrings, then fold, weld, cut, and finally put the finished product into the box, and fold it away.

2. Production flow chart

Nowoven insertion → Nose bridge → Welding embossing → Punch valve hole → Traction→ Printed trademark→ Welding ear bands → Folding → Welding edges → Cut-out →Close-up → Finished products in the box

3. The whole plant production equipment

1)Unwinding mechanism (6 stations) 1 set

2)Nose bridge strip unwinding mechanism 1 set

3) Nose bridge straightening mechanism 1 set

4) Nose bridge driving and cutting mechanism 1 set

5) Nose bridge strip placement mechanism 1 set

6) Flow welding device 1 set

9) Two sets of trademark agencies 2 sets

10)Two sets of automatic welding ear strap mechanism 2 sets

11) A set of automatic servo shearing mechanism for welding ear band 1 set

12 ) One set of folding mechanism 1 set

13 ) Welding edge mechanism 1 set

14) A set of automatic servo tracking shearing mechanism for welding edge 1 set

15) cutting mechanism 1 set

16 〉 A set of fast conveying mechanism 1 set

17 〉 A set of border collection agencies 1 set

18 〉 Electrical control system 1 set2 Detailed composition of KN95 mask production line

4. Installation and commissioning

1) The unit should be placed in a good plane.

2) Place each part of equipment according to the production line layout drawing, and calibrate the centerline and level of the unit. The distance between auxiliary machines can be adjusted appropriately according to the situation of the workshop site.

3) The unit's electrical equipment must be well grounded.

4) After the installation is completed, connect the electric and gas pipelines.

5) Check whether all parts are loose or falling off.

6) Check whether the transmission parts rotate normally.

7) Separately debug each part of the equipment, and then enter the whole machine debugging after the operation is normal.

Ningbo Hautek Import & Export Co.Ltd.

Contact Person: Frank Huang

Telephone: +86-13805862932

Landline: 0574-87317986

Company Address: 831,No.598 Jiangnan Rd., Ningbo, China P.C.315040.

Website: hautek.us764.com

Previous: Full-Automatic Disposable Flat Ma...